"Project Clean Oceans"

Global Water Optimization

Our Solution

Great Ocean Garbage Collectors

Technology invented by Randy Hatton called the "Great Ocean Garbage Collectors," is designed to remove large volumes of garbage from our oceans efficiently, effectively, and with the least harm to sea life.

Randy's thirty-five years of commercial fishing experience gave him the knowledge necessary to create this technology. He worked on the most advanced, large scale fisheries in the world. He developed these ideas from knowledge gained and his deep love and passion to give back to the oceans. Instead of hauling fish like you see in picture, it will be tons of plastic.

Project Clean Oceans is one of the most important goals for our planet today. Give us eight years, and the plastic majority of the plastics and chemicals in our oceans will no longer be an environmental disaster. Our work will support the world's oceans, thereby preventing millions of innocent and unnecessary marine life deaths. We have recently upgraded the design in 2025 and are not currently showing the new version, his will be shown in 2026.

.

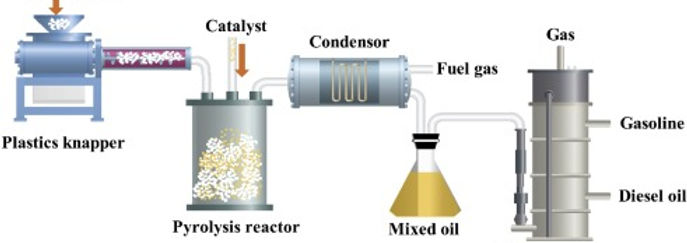

Latest technologies convert plastic waste to fuel, primarily via advanced pyrolysis (heating without oxygen) or hydrothermal processing, often using novel catalysts or conditions like water-based reactors for lower temperatures, yielding liquid fuels, chemicals, and even hydrogen, with newer methods tackling tricky plastics like PVC by capturing chlorine, aiming for lower emissions and higher efficiency than older methods.

Key Technologies & Innovations:

-

Advanced Pyrolysis: Heating plastics in low-oxygen environments breaks them into smaller molecules, producing oils, gases, and char, with new catalysts (like activated carbon) boosting yield and efficiency.

-

Hydrothermal Processing (HTP): Uses high-temperature, high-pressure water to break down plastics like polypropylene into oil, essentially reversing the original manufacturing process.

-

Catalytic Hydrogenolysis: Uses hydrogen gas and catalysts to convert plastic polymers into transportable liquid fuels.

-

Ionic Liquids for PVC: Chemists use special ionic liquids to break down chlorine-heavy PVC, safely capturing the chlorine and converting the rest into gasoline-like fuels, a major breakthrough for difficult plastics.

-

Low-Temperature Chemical Recycling: New processes convert single-use plastics into high-value fuel precursors without releasing CO2, often in under two hours.

-

Self-Sustaining Systems: Some systems are designed to use the small amount of LPG produced as fuel to power the process itself, making them energy self-sufficient.

Benefits & Goals:

-

Reduces Landfills: Diverts massive amounts of plastic waste from landfills and oceans.

-

Creates Valuable Products: Produces liquid fuels (diesel, jet fuel), chemicals, and hydrogen.

-

Improves Efficiency: New methods are faster, work at lower temperatures, and handle mixed plastics better.

-

Lower Emissions: Aims to reduce greenhouse gases and pollutants compared to incineration.

These technologies are moving from research labs to pilot projects, with companies collaborating to scale up for commercial use, offering a way to create a circular economy for plastics.

Latest technologies turn plastic waste into building materials like strong, interlocking blocks, panels, and composite lumber using advanced methods such as direct thermal compression (no sorting), chemical oxidation (breaking down molecules), and mixing with other waste to create durable, sustainable alternatives to concrete, reducing landfill and carbon footprints. These innovations, often involving modular designs, offer cost-effective, strong, and sometimes earthquake-resistant solutions for affordable housing, infrastructure, and furniture, with some processes even eliminating the need for resin or sorting.

Key Technologies & Products

-

New-Cycling & Thermal Compression: Companies like Westec Global and Lup fuse mixed plastics (even unwashed) under heat and pressure into interlocking blocks or panels, preserving material strength and reducing water/chemical use.

-

Plastic-Sand Composite: Startups, particularly in Africa, shred plastic, mix it with sand, then heat and compress it into bricks that are stronger and cheaper than concrete.

-

Chemical Recycling (Advanced Recycling): Platforms like BOTTLE (NREL) use processes like chemical oxidation to break down hard-to-recycle plastics (like chip bags) into their molecular building blocks for new materials.

-

Extrusion & Composite Materials: LIXIL uses technology to crush and extrude waste plastic with wood into durable, circular building materials.

-

Plasma Technology: A "world first" plasma torch technology can turn mixed plastics into basic chemical building blocks at high speeds, notes Bishopstrow College.

Applications & Benefits

-

Bricks & Blocks: Modular, interlocking blocks for quick, affordable housing and schools (e.g., Kubik, ByFusion).

-

Panels & Walls: Earthquake-resistant, waterproof panels for various structures.

-

Roads: Plastic-infused roads that are more durable and require less maintenance.

-

Furniture & Interiors: Stylish furniture and wall panels from recycled plastics.

-

Benefits: Reduced landfill waste, lower carbon emissions (compared to cement), cost savings, increased durability, and job creation.

How It Works

The Great Ocean Garbage Collectors are intended for ships similar to large-scale (Mid-Water Trawl) commercial fishing vessels called catcher/processors.

These ships will be equipped with the most advanced technology to process and recycle the plastic into fuel and building materials while still at sea. We will use our recycled materials, grade A to fuel the ship and grade B to make modular blocks.

These modular blocks will be constructed using specially designed casings, allowing air pockets in the center for better insulation value. These are then coated in a UV-resistant polymer to keep the materials from photo-degrading. Once the ship is filled with the modular blocks, it will return to port and be sold as building materials for profit.

Latest technologies turn plastic waste into building materials like strong, interlocking blocks, panels, and composite lumber using advanced methods such as direct thermal compression (no sorting), chemical oxidation (breaking down molecules), and mixing with other waste to create durable, sustainable alternatives to concrete, reducing landfill and carbon footprints. These innovations, often involving modular designs, offer cost-effective, strong, and sometimes earthquake-resistant solutions for affordable housing, infrastructure, and furniture, with some processes even eliminating the need for resin or sorting.

Key Technologies & Products